The Birth of a Pin

Explore the magical process of pin making! Ever wondered how those amazing badges come to life? Let's take a peek into the fascinating world of badge making!

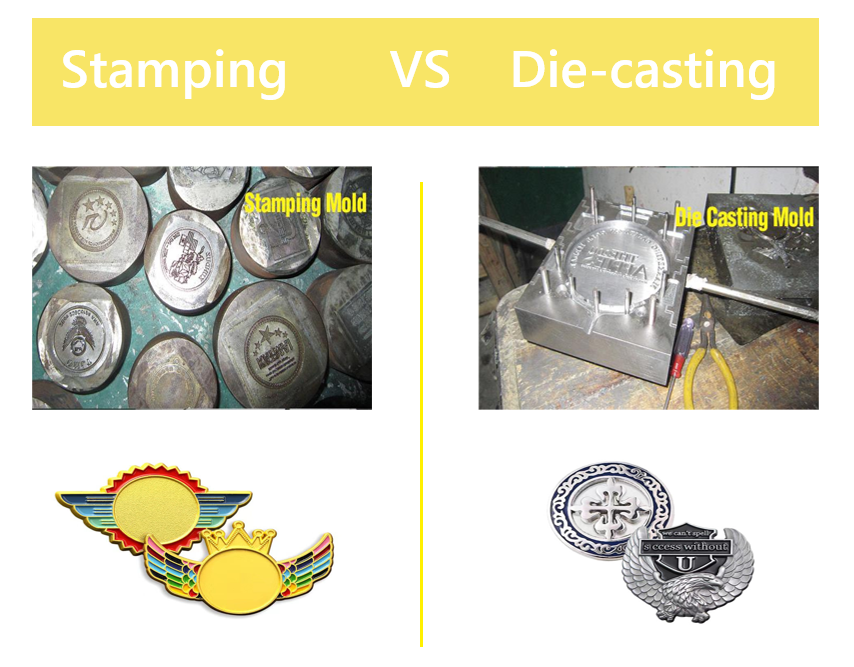

Stamping Process

The stamping process involves engraving a stamping die and then using pressure to stamp from top to bottom on a sheet of metal to press out the shape of the pins.Stamping is often done with materials such as copper, iron and aluminium, with copper being the most common. The softer nature of copper allows the front of a stamped pin to have clear lines, a fine relief and a 3D effect. It should be noted that the stamping process limits the design of the back side, which is usually flat and cannot be hollowed out.

Die-casting

The die-casting process, in which liquid metal is injected into a mould and cooled and solidified under specific temperature and pressure conditions, is exquisite and highly accurate. Its most commonly used material is zinc alloy. Die casting process can produce more difficult and more complex and exquisite pins, such as pins with hollowing effect,3D pins and so on.

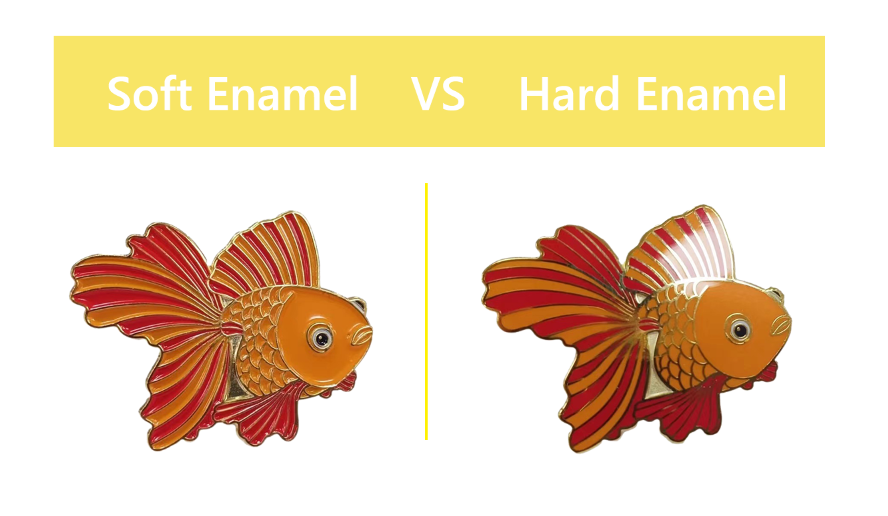

Soft Enamel Pins

Soft enamel pins are one of our highly popular choices. The most obvious features of baked enamel brooches are their strong indentations, vibrant colours and clear lines. By running your finger lightly over the surface of a soft enamel brooch, you can feel the raised edge of the metal above the paint-filled area. This raised edge and recessed areas give a striking 3D effect in the light.

Hard Enamel Pins

Hard enamel custom badges are crafted with precision, seamlessly integrating enamel colors with the metal borders for a smooth and glossy surface, reminiscent of ceramic texture. This high-end badge type maintains its vibrant colors for decades, making it particularly suitable for occasions that demand sophistication and refinement.

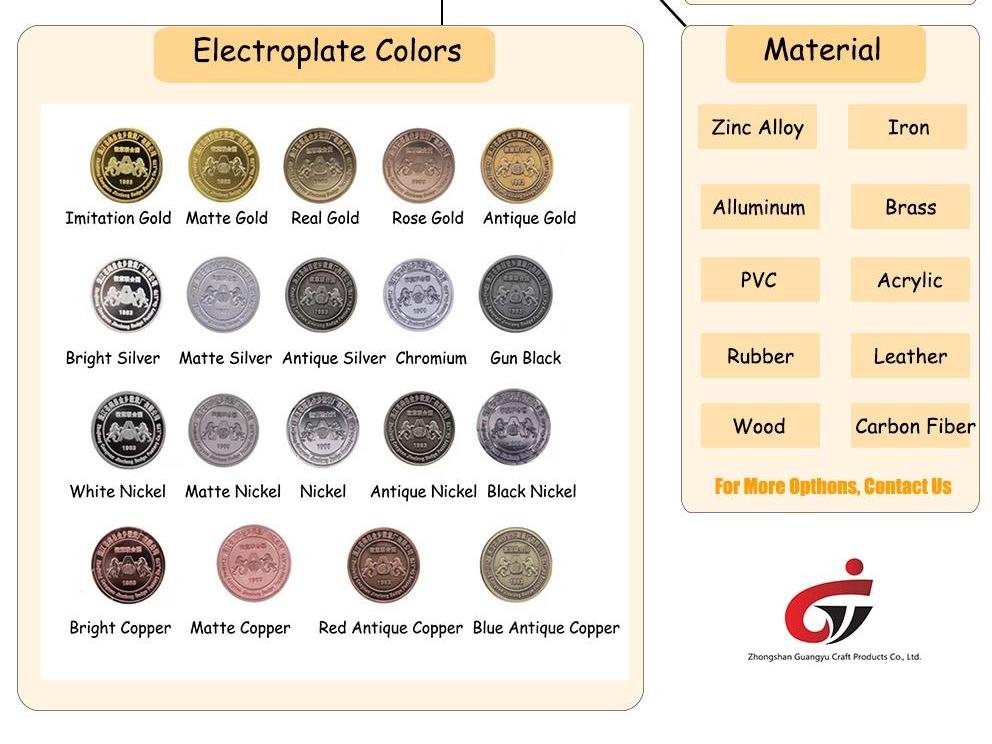

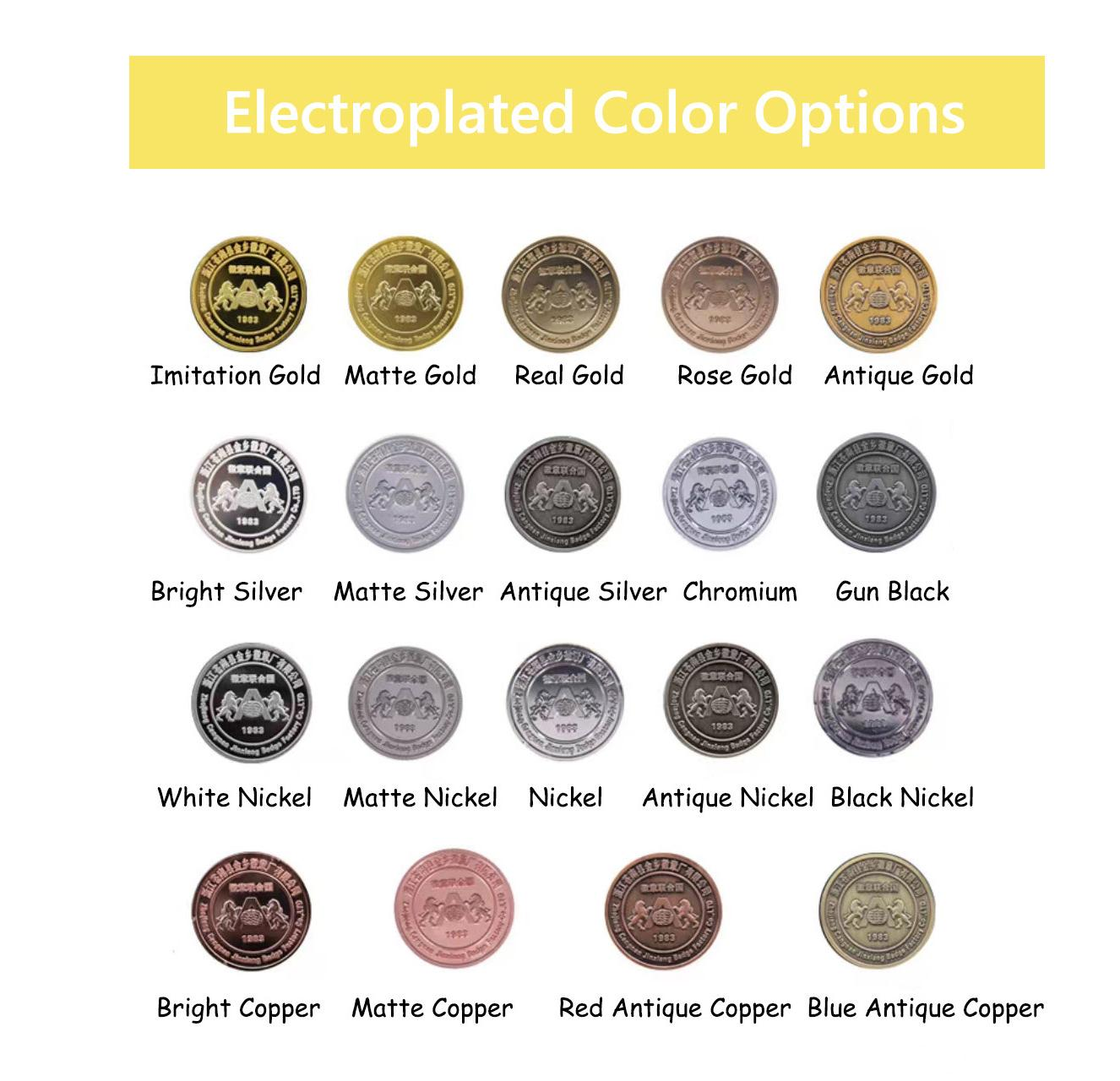

Electroplated

We use advanced electroplating technology to add a solid plating layer to the surface of the keychain. It not only enhances the appearance and texture of the product, but also has anti-corrosion and wear-resistant properties, ensuring that the product remains lustrous for a long time.

Printing&Dripping

Printing process is to print the customised pattern onto the pin through UV printing, screen printing,spray painting and etc. The feature of this process is that it can do gradient colour pattern and the cost is low.

Dripping process is to cover the printed pattern with drops. The coating gel can effectively protect the surface of the pins, make it have certain waterproof and dustproof performance, and increase the three-dimensional sense of the front of the pin. At the same time the smooth colloid also provides a better touch feeling for the pins.

We focus on interaction with our customers and always maintain transparent and efficient communication from design to production. Customer satisfaction is our greatest pursuit, and each badge carries our heart and commitment.

A customised badge is not only an object, but also a status symbol. Through our service, customers are able to show their personality and uniqueness in every place, making badges become the shining point in their life. Feel free to contact us to create a unique badge that shows your personality and taste.